0.5kg Engine Room Electric Automatic Fire Equipment

Product Description

WF-ACD0.1/0.3/0.5-XQ Auto-suspended DCP Fire Extinguisher

User Manual

I Introduction

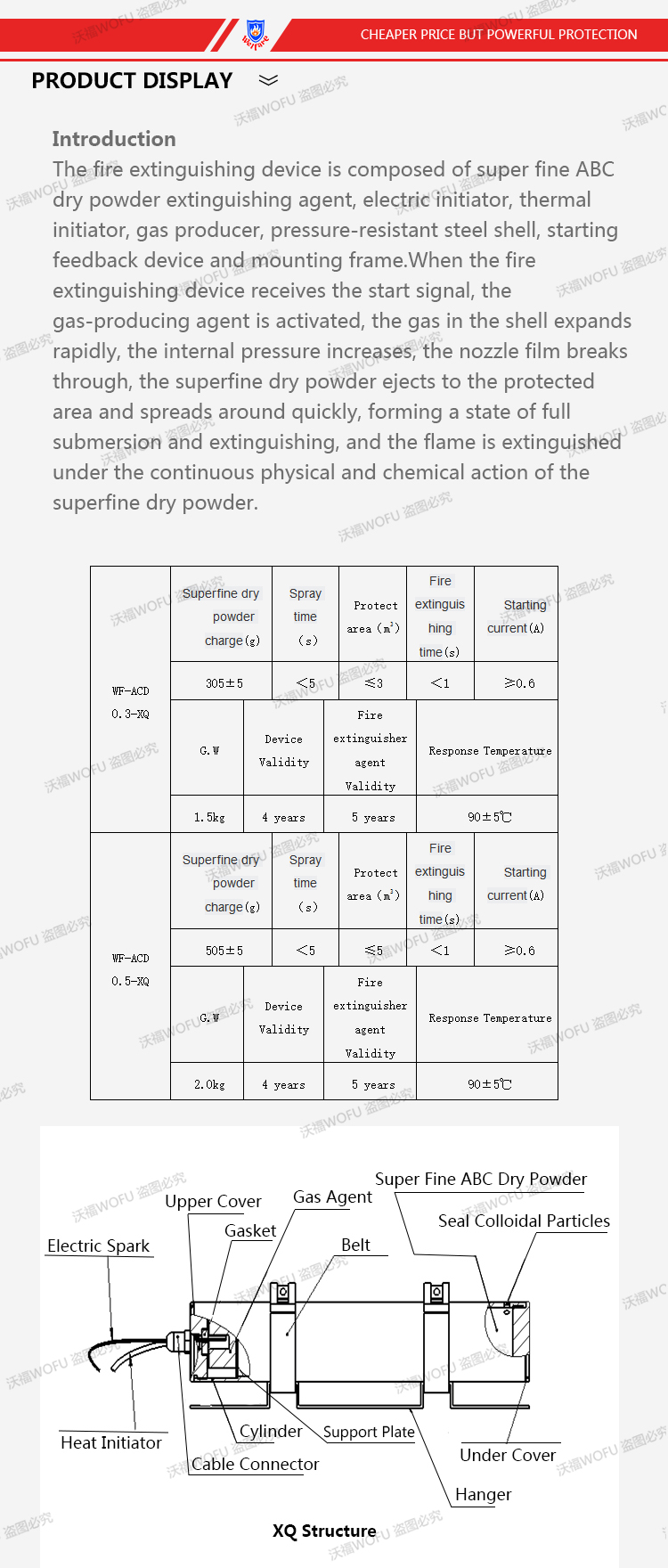

WF-ACD0.1/0.3/0.5-XQThe suspended dry powder fire extinguishing device (hereinafter referred to as the fire extinguishing device) has the characteristics of "quick response, early alarm, efficient fire extinguishing, ecological environmental protection".The fire extinguishing device is composed of super fine ABC Dry Powder Extinguishing Agent, electric initiator, thermal initiator, gas producer, pressure-resistant steel shell, starting feedback device and mounting frame.When the fire extinguishing device receives the start signal, the gas-producing agent is activated, the gas in the shell expands rapidly, the internal pressure increases, the nozzle film breaks through, the superfine dry powder ejects to the protected area and spreads around quickly, forming a state of full submersion and extinguishing, and the flame is extinguished under the continuous physical and chemical action of the superfine dry powder.

II. Product features

1. Full functions, reliable performance and convenient installation.

2, fully sealed design, with waterproof, moisture-proof functions.Reliable quality and long service life.

3. Fast start speed, high fire-fighting efficiency, with characteristics of early fire-fighting.

4, can be linked with the alarm, to achieve automatic start, manual start and other functions.

III. Scope of application

It can quickly extinguish class A, B and C fires and live electrical fires.It is suitable for cable interlayer, cable tunnel, cable trench, electromechanical cabinet, automobile engine room, etc.

IV. Mechanism and technical parameters

Fire extinguishing device is composed of shell, super fine ABC dry powder extinguishing agent, gas production device, thermal initiator, electrical initiator, starting feedback device, etc.

Modle No. | Superfine dry powder charge(g) | Spray time (s) | Protect area(m3) | Fire extinguishing time(s) | Starting current(A) | ||||||

WF-ACD 0.1-XQ | 102±2 | <5 | ≤1.0 | <1 | ≥0.6 | ||||||

G.W | Device Validity | fire extinguisher agent Validity | Response Temperature | ||||||||

1.3kg | 4 years | 5years | 90±5℃ | ||||||||

WF-ACD 0.3-XQ | Superfine dry powder charge(g) | Spray time (s) | Protect area(m3) | Fire extinguishing time(s) | Starting current(A) | ||||||

305±5 | <5 | ≤3 | <1 | ≥0.6 | |||||||

G.W | Device Validity | Fire extinguisher agent Validity | Response Temperature | ||||||||

1.5kg | 4 years | 5 years | 90±5℃ | ||||||||

WF-ACD 0.5-XQ | Superfine dry powder charge(g) | Spray time (s) | Protect area(m3) | Fire extinguishing time(s) | Starting current(A) | ||||||

505±5 | <5 | ≤5 | <1 | ≥0.6 | |||||||

G.W | Device Validity | Fire extinguisher agent Validity | Response Temperature | ||||||||

2.0kg | 4 years | 5 years | 90±5℃ | ||||||||

V. Installation

(I) engineering installation

1. Fire extinguishing device shall be started by grouping according to the status and size of the protected space or protected object, and shall be mounted on the top or side of the building or protected object in combination to ensure that the nozzle is aligned with the protected object (by mounting the bracket at an adjustable Angle).

2. Fix the mounting base on the top or side of the building or protective object, then hang the fire extinguishing device and tighten the bolt to ensure the opening of the fire extinguishing device is aligned with the protection zone.

(II) installation in the engine compartment

1. The nozzle of the fire extinguishing device (which can be adjusted by the support) should be aligned with the flammable part during installation. The maximum straight-line distance between the nozzle and the protected object should be between 0.5 and 2.5 meters.In view of the complicated engine mechanism and the large convex and concave surface, in order to properly install the fire extinguishing device, the following requirements should be configured: 1 to 3 cars, 3 to 5 front engine nacelle for passenger cars and trucks, 4 to 5 rear engine nacelle for passenger cars.

2. Fix the fire extinguishing device in the car engine compartment.Fix the position and direction so that the nozzle of the fire extinguishing device is facing the protection object, and tighten it to prevent loosening after vibration.

3. In the active start mode, the working voltage of the manual fire button (with temperature sensing element) is 12V or 24V, and the manual button is fixed in the driver's easy place in the cab.(the connection of the temperature sensing element is directly to the power supply in the engine room)

4. Connect the power cord after connecting the fire extinguishing device.

The electrical initiator and starting feedback device of the device shall adopt the wiring terminal shown in the figure below. The terminal 282104-1 (common terminal) is connected to the electrical initiator, and the terminal 282080-1 (parent terminal) is connected to the starting feedback device.

5. Installation of heat initiator

(1) the heat initiator is connected by joint, glass fiber protective sleeve and then by nylon tie belt.In order to ensure the reliability of fire connection, the heat initiator coated plastic on the device can be cut with a cutting tool to make a 3-5cm hole before lapping.

The heat initiator should be firmly fixed in the upper part of the engine compartment, away from the exhaust pipe and other overheating parts of more than 30 cm, to avoid the unstable fixation, when falling off lap in the overheating parts of the phenomenon, so as not to cause misoperation.

VI. Instructions for use and maintenance

1. The management personnel shall check the appearance of the fire extinguishing device regularly. If the aluminum foil at the nozzle of the fire extinguishing device is damaged, the fire extinguishing device is fixed and loosened, and the heat initiator is disconnected and loosened, it shall be replaced and repaired in time.

2. During other construction on site, attention should be paid to avoid contact with heat initiator at high temperature above 100℃ to avoid wrong operation.When disassembling fire extinguishing device, please ask the professional personnel to understand the performance of fire extinguishing device on-site guidance.

VII. Transportation and storage

Transport light handle light, strictly prohibited throwing, to prevent collision, avoid exposure to the sun, rain.The storeroom shall be ventilated, dry and clean and shall not be stacked more than four storeys.

VIII. Unpacking and inspection

1. Check whether the instructions, accessories and list are complete when unpacking.

2. Check whether the fire extinguishing device is damaged.

IX. Validity period of use

The validity period of the fire extinguishing device is 5 years (4 years for vehicle use). After the validity period, please contact the local dealer or manufacturer for replacement.

X. matters needing attention

1. The installation personnel shall undergo professional training.

2. Open fire, electrification and high-temperature operation must be avoided during installation.

3. During installation, please pay attention to protect the nozzle and direct the nozzle towards the place prone to fire.

4. Ensure that the electric initiator is short-connected during the installation process and before it is put into use, so as to prevent incorrect operation of the device.

5. The equipment shall be inspected regularly every year, and the maintenance shall be conducted by professional fire protection qualified manufacturers.

6. During maintenance, first disconnect the heat initiator and power supply, and restore to original state after maintenance.

Note: this product contains inflammable and explosive dangerous goods. Open fire is strictly prohibited in the process of transportation and storage!

Product Categories : Fire Suppression System > Bus Fire Suppression System

Premium Related Products